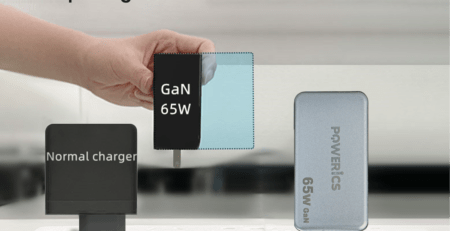

The rapid mobilization of gan power electronics has transformed industries that range from consumer electronics to aerospace and even defence and military technology, and it has found a foothold in EVs and renewable energy systems. Engineers and Businessmen alike have been drawn to gan technology because of its reliability as well as its promised higher power efficiency as well as reduced operating costs compared to silicon. But one question remains at the heart of all gan adopters; can it deliver long term durability under real world conditions?

This is where the rigorous reliability testing of gan devices comes in. By adhering to standards following global gan reliability standards and applying the best practices, manufacturers can make sure that their products meet the expectations of such high demanding applications.

Standards for GaN Reliability Testing:

Certain frameworks have been set in the semiconductor industry that organizations follow, they are:

- JEDEC Standards: Widely recognized, provide rest methods for device level reliability including thermal recycling, high temperature storage and electrostatic discharge.

- AEC-Q101: This is crucial for automotive applications, it ensures that the gan device reliability meets the most stringent requirements of electronic vehicles and other electronics in the automotive industry.

Best Practices in GaN Reliability Testing

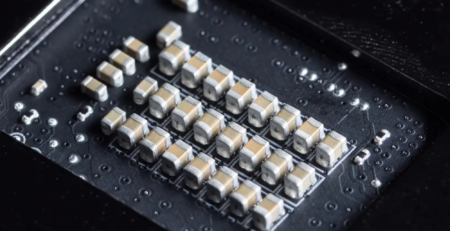

- Accelerated Stress: Basically, involves simulating years worth of wear and tear in the span of a week that helps identify the weak point in the gan power electronic device. Stress testing, high voltage testing, extreme temperatures, fast switching cycles, exposes potential lifetime testing, issues early in development.

- Failure Mode: Understanding various failure modes such as gate oxide degradation, thermal overstress, facilitates improvements.

- System Level Validation: Testing for real world complications such as sudden load changes, transient spikes as well as electromagnetic interferences must also be replicated in reliability challenges in gan power electronics.

- Continuous Monitoring: Devices should be monitored over extended tie periods in initial applications. Data that is collected through these applications must be then used for long-term testing that will help validate models which makes manufacturers for mass scale deployment.

Conclusion:

The cornerstone of trust in any power electronic device is reliability. For gan power electronics to not only meet rising expectations, but to surpass them and cement themselves in the electric industry, robust reliability testing is non-negotiable. With rigorous reliability testing and proactive analysis, engineers can make sure that these devices can not only perform better but also last for a longer period of time. Doing so will make sure that gan based power electronics will stay at a competitive advantage for years to come.

Leave a Reply