As GaN power devices have gained traction in the rapidly evolving world of power-electronics, for their ability to handle higher switching speeds and frequencies, delivering superior energy efficiency as well as for their lighter, smaller and compact designs, the question still remains, no matter how cutting edge, every technology has its own engineering challenges, and one such vital engineering challenge is GaN thermal management. While gallium nitride thermal conductivity is better than silicon, the compact footprints and high power densities leave concentrated heat. If this heat dissipation is not quelled properly then it can lead to performance degradation, reliability issues, or even premature device failure.

Why is Thermal Management very important in GaN Devices?

Contrary to silicon devices which have been used for decades with more mature design practices, high-frequency gan devices work under unique stress conditions. They have faster switching speed that curbs energy loss, but it can also lead to generation of centralized hotspots that normal cooling methods might not handle well. Poor thermal design in gan circuits will result in safety complications but will also affect the lifetime of the device. In vital applications such as EVs, data centres as well as aerospace and defence tech, this is an unacceptable risk.

Strategies for Managing Heat in GaN Devices

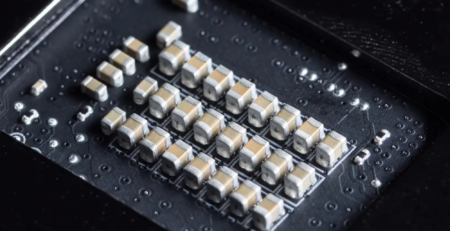

- Advanced Substrates & Packaging: Using substrates with high gallium nitride thermal conductivity improves heat transfer away from the active region. Today’s packaging technologies such as chipscale packages and enhanced thermal pads play a vital role.

- PCB Layout Optimization: Utilizing good layout is essential for managing heat, using copper traces, thermal vias as well as multilayer PCBs can distribute heat more effectively.

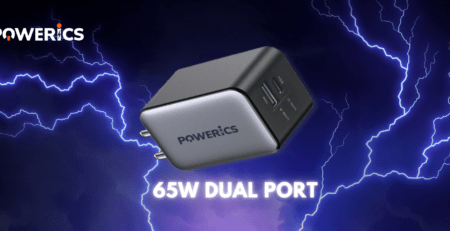

- Passive and Active Cooling: While many devices rely on heatsinks and natural convections, high-powered applications will need forced air or liquid cooling to maximize gan heat dissipation.

- Thermal Simulation Tools: Engineers need to first run simulations in order to identify thermal bottlenecks. This therefore reduces the need for expensive redesigns.

Real World Implications of Substandard Thermal Management:

Ignoring thermal design in gan circuits does not just reduce effectiveness, but it also increases operating costs and limits the adoption of the said device in industries where efficiency and reliability is non-negotiable. For example, in data centres, substandard cooling will only increase the energy consumption dramatically, negating any advantage that the gan device brings.

Conclusion:

Efficient GaN thermal management is critical to high-frequency GaN devices’ performance and dependability. Engineers can overcome thermal obstacles and realize the full potential of this wide bandgap technology by combining cutting-edge materials, clever design principles, and contemporary cooling techniques. Those who are adept at controlling heat in GaN devices will be at the forefront of innovation as industries seek more compact and efficient power solutions.

Leave a Reply